|

InvertaSpot GT - New

Now with MATERIAL

TEST:

CLICK

HERE TO SEE DEMONSTRATION

Single Sided Gun and full set of electrodes available

How do you know what type of steel that is to be welded?

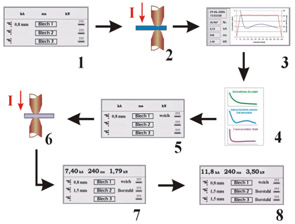

The InvertaSpot GT has now been fitted as standard, with the latest

MATERIAL TEST® program which not only determines the individual

types of steel and galvanised coatings, but also sets the welding

parameters so that the final results are perfect. No longer is time

wasted trying to find this information and no chance of errors.

No problems, no fuss, no mistakes!

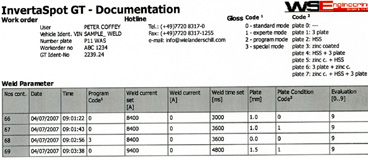

Full

traceability is essential for PAS 125

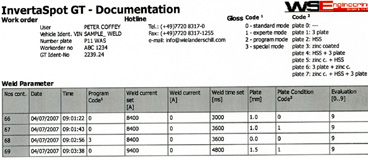

A vital requirement of all new spotwelding equipment is that it

be able to show evidence of the quality of every spotweld completed.

With the InvertaSpot GT this information is printed on A4 paper

showing all aspects of the weld.

The InvertaSpot

GT always remembers the date and time as well as:

• The Job Number

• VIN number

• Car registration number

• Operator's name

Every weld is

recorded during each job for printout later. Never be without evidence

of the job being done correctly!

Car

manufacturer requirements…….It is tough to keep up with

them!

With many new steels being introduced in to the latest range of

cars, it is essential to have the correct equipment to weld them.

On several cars (Volvo, Peugeot and others) already in the market

today, the welding requirement is over 12,000amps at 500dAN. Other

cars are coming along in 2007 that will require the same. It is

impossible to carry out the repairs correctly if your existing welding

machine has a maximum output of only 9,000amps.

With the InvertaSpot GT you can have complete peace of mind. 13,000amps

at 550dAN is far above what is being asked for. This extra capacity

is needed.

Future Proofed………………….No need

to change your welder in the future!

Future proof your welding equipment, invest in the InvertaSpot GT

now and be ahead of the game for years to come.

We know that every bodyshop manager is fed up with having to invest

in new spot welding equipment every year, just because the steel

on the latest cars has changed.

Now the times are changing. The InvertaSpot GT is designed to work

on all steels and on all cars.

By investing in the InvertaSpot GT, there is no need to worry about

the future. It has the extra capacity to work even up to 14,000amps

at 600daN.

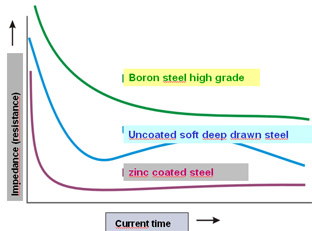

Constant Current Control……….Constantly checking,

Constantly correcting!

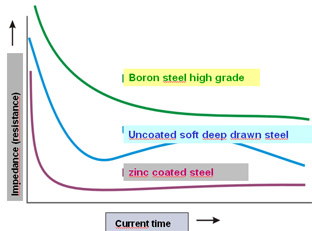

The InvertaSpot GT will always give the correct amps to every weld,

no matter how thick or what type of steel is being used.

The control board first checks the impedance of the job and continues

to works out the power requirements automatically throughout the

whole weld taking into account any other interferences from paint,

glue or power to the workshop.

This is the first time this type of regulation control has been

used and ensures factory welds (size, shape and strength) for the

workshop even using a 32amp power supply. The InvertaSpot GT will

ensure complete peace of mind at all times.

No Magnetic field………………Be ready

for the EU Directive 2004/40/EG

According to EU law, every company owner is responsible for the

health and safety of the staff. The new InvertaSpot GT welder has

a magnetic field of less than 30% of the permitted legal limit whereas

the existing spot welders are 20 times over the limit.

With InvertaSpot GT you are fully compliant. The EU Directive has

been put on hold until 2012, but this still means it is vitally

important to respect the welfare of your staff, so when purchasing

new equipment always buy EU compliant equipment.

An accident waiting to happen……….Don't let it

happen to you!

Already we know that damaged cars are being inspected by various

safety agencies to see if past crash repairs have been carried out

correctly. If proved not to be the case, the repairer is likely

to be held responsible. If a fatality occurs then serious charges

could be made against the repairer.

Make sure your welding equipment is fully up to date, that you can

weld the new steels and that you are able to prove the results.

Water-Cooling………………….Productivity

is high even at 13,000amps

The tips, electrode arms and both transformers are fully water-cooled.

The 80litre reservoir ensures that welding at 13,000amps can be

successful all day long without any overheating problems.

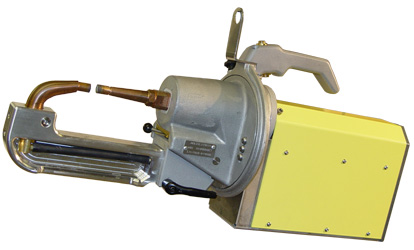

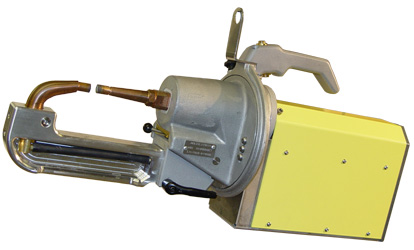

Twin sided C Gun Absolutely essential when welding above 10,000amps

To hold the nugget in place during the weld, the clamping force

must be above 450daN. This is not possible with the normal X gun.

The new style of welders will now all be supplied with a C gun.

The Compact

body is easily manoeuvred and there are different arms for different

applications. It is relatively light to lift (less than 5lbs using

the balancer) and of course there is water-cooling at the tips,

arms and the transformer.

Quality Control… A brief summary

The memory card remembers all aspects of 100,000 spotwelds and this

information is easily printed onto A4 for each job.

Welding at 13,000amps generates enormous heat. The full water-cooling

system on the InvertaSpot GT ensures the workshop can weld at maximum

amps and keep working all day if needed.

Constant control of Current, Voltage, Impedance and Energy.

Absolute and Relative impedance measuring whilst compensating for

any interference from paint, glue or other outside sources.

The finished welds are the same size, shape and strength as the

original.

This is as close as you can get to producing a factory weld in

your workshop.

User friendly

• Easy to move around the bodyshop

• The dialogue on the front screen is very simple to understand

• Easily updated through a memory card

• Individual programs for any user plus OEM programs when available.

• Process control depending on the different steel qualities

Click here to see accessories available

for the InvertaSpot GT

Click

here to view other machines available

For more information and to register for updates by email, please

click here.

|

|

|